Q: The valve seems to be inside the fitting. How many types do you have (threads, couplings, nominal sizes, materials) In case we will be allowed to assemble the system, which type of ferrule do you have?

A: If the question is referring to the end fitting we offer male NPT, Female NPT, Miscellaneous Flanges. As far as ferrules they are machined from pipe and the drawings are available. The fittings are standard except for the portion that is below the end connection. Therefore we can use any end connection including JIC swivel as the “LifeGuard Safety Hose” part is inside of the unit. Two styles of LifeGuard Safety Hose shut off couplings are known as LifeGuard I, II. In addition, The each style can be combined with our patent pending Tri-Bolt Breakaway Coupling shown below:

LifeGuard I is used for most small hose applications, ¼ – inch to 1¼ – inch. The coupling is constructed of monel, brass, or stainless 316. LifeGuard II is used with 1 ½” inch and 2-inch hoses and the coupling is constructed of Monel, stainless 316 steel, or carbon steel. LifeGuard II is used with most large hose diameters, 1½ – inch to 6 – inch. The coupling is constructed of stainless 316 for most applications.

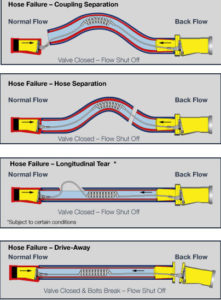

A: The ECP is inserted within the hose thus producing the necessary force. The ECP is inserted when the hose is coiled with the ECP travelling around the OD of the coiled hose. During normal operation they are kept open by a coated ECP incorporated within the hose bore. This ECP is acting as acompression spring providing thrust in the direction of both ends of the hose, holding the valves open. The ECP thrust is carefully determined to insure against premature closure. Should this thrust be eliminated due to coupling ejection, hose stretching or hose separation, the valves are released and instantly seat, stopping flow in both directions. The picture below illustrates this principle.

A: The force does not come only from the ECP. When the ECP is sufficiently relaxed due to the increasing length of the hose resulting from stretching, pullaway, end attachment rupture, the force comes from the flowing product against the valve surface that is intentionally positioned in the flow. If there is no flow in a pullaway, the ECP will close the valve.

A: This is not possible for a hose to separate and the ECP to stay tense. Once the hose has separated, the ECP now has space to reach its uncompressed length. When this occurs, even absent any back pressure seating the valves or flappers, the valves will seat. This question is similar to asking what would happen if a spring that is being compressed is no longer compressed – will it extend itself.

A: Once again, The ECP is serpentined in the hose thus producing the necessary force. The ECP is inserted when the hose is coiled with the ECP traveling around the OD of the coiled hose. During normal operation they are kept open by a coated ECP incorporated within the hose bore. The ECP thrust is carefully determined to insure against premature closure. Should this thrust be eliminated due to coupling ejection, hose stretching or hose separation, the valves are released and instantly seat, stopping flow in both directions. If the hose separated and there was no pressure, the units would be located within the same location and the seating area but without any pressure, there is no need for the seating requirement.

A: First, the cost of various breakaway devices can be extremely expensive and provides a lesser degree of safety. An example is the dry break away coupling typ ABV-S ( with cable) 2″BSPP male thread x 2″BSPP male thread made of stainless steel 1.4571, seals made of PTFE, o-rings made of viton price each pcs 738.65 euros net and it does not include the hose (add an additional $350 euro) and it does not protect the other side of the hose.

Product benefits:

LifeGuard Safety Hose is a technology that reduces the consequences, associated with certain hose ruptures. It may also reduce operating costs by eliminating an operator’s position in cases where government regulations require constant personnel attention while using hoses. We have sold in excess of 300,000 hose assemblies over the last eight years for the following applications: High Pressure Cylinder Filling (¼” to 1”), cryogenics transfer (¼” to 1”), cryogenics trailer hose (1”-2”), LP (units from ¾” to 3”), NH3 (in size from 1” to 6”), SO2 (2”), Metallic hose (from ½” to 2”), CO2 (½” to 2”), HCL (at 1”), Chlorine (1-2”), Petroleum Transfer (2-3”), General Chemical (1”-2”) of such hoses to companies like Shell, Dow Chemical, Dow Corning, Amerigas, Linde, Air Liquide, AGA Sweden, BASF, PPG and others. The ExxonMobil Fuels and Marketing group has decided to recommend its use for LPG distribution in Europe and in the United States.

A: We will confirm this information once we have our quality control personnel evaluate the standard.

A: Minimal turbulence. Tests performed by Air Liquide, Independent Laboratory and Linde Gas/AGA were unable to determine any changes in flow caused by turbulence.

A: If this question really means “How difficult is the engineered compression springs system”, the answer is very simple. The ECP takes to OD of the hose and our mass manufacturing process will demonstrate this at the upcoming meeting.

A: Any threads if the volumes are justified. Since the fittings are cast, we can machine them to any specification necessary. There is sufficient material available prior to machining for a variety of threads.

If you have questions, comments or feedback, please feel free to contact us.

We are ready to help!