LifeGuard Technologies is formed to take the next steps by providing, on a geographical basis, reliable, readily deployable and cost effective improvements in industrial safety. As the name declares we are a Global Company that is based upon the extensive experience of its founders and joint venture partners and believes that significant and measurable enhancements to industrial safety are achieved with deployment of “passive devices”. The essence of our mission is to increase the safety of all operations and facilities through the deployment of highly safe systems thru advancements on existing technology.

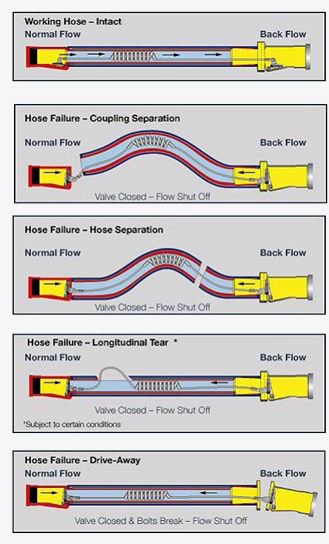

We have completed developed two advancements on the Smart-Hose technology that we previously invented. The new technology, known as the Tri-Bolt Breakaway Hose, combines a similar safety concept to the Smart-Hose technology that we invented but with (1) a more advanced internal spring system and (2) with a Breakaway design .

The system has a flapper valve on each end, one in a position that you are familiar with and the other on the outside of the breakaway flange. The breakaway as you can see from the pictures and drawings is a three-bolt flange with the bolts engineered to release after app. 1200 pounds of force is applied to them. To put this in perspective a regular hose assembly will not fail until 5,000 pounds plus is exerted upon the hose.

This is typically far more than either the truck or stationary piping is designed to withstand. The flapper, as you can see will seal “behind “ the breakaway flange forming a seal on both sides. I think that it is also apparent by the pictures and the drawings that the breakaway flange is almost imperceptible, needs to be only on one-side of the hose and will not interfere in any way with operation. It is light-weight and streamlined. The bolts are engineered with existing and proven technology and are familiar to many in our industry as reliable. I have attached test documents showing the breakaway characteristics of the bolts.

The flappers are held in the open position by a compression spring. This spring (obviously of material compatible with the medium) is light weight and very durable, in fact there is no difference in weight between this new system and older competing products. The spring will be one piece from end- to-end and will have the spring part occupying about two feet in the middle of the hose. The spring will have on each side (again this is one piece) straight metal spring steel that will insert into the flapper holding it open. This basically looks like a two foot spring with about 9 feet of straight spring steel protruding from each side. The introduction of advanced spring technology has several important advantages:

The system has a flapper valve on each end, one in a position that you are familiar with and the other on the outside of the breakaway flange. The breakaway as you can see from the pictures and drawings is a three-bolt flange with the bolts engineered to release after app. 1200 pounds of force is applied to them. To put this in perspective a regular hose assembly will not fail until 5,000 pounds plus is exerted upon the hose.

This is typically far more than either the truck or stationary piping is designed to withstand. The flapper, as you can see will seal “behind “ the breakaway flange forming a seal on both sides. I think that it is also apparent by the pictures and the drawings that the breakaway flange is almost imperceptible, needs to be only on one-side of the hose and will not interfere in any way with operation. It is light-weight and streamlined. The bolts are engineered with existing and proven technology and are familiar to many in our industry as reliable. I have attached test documents showing the breakaway characteristics of the bolts.

The flappers are held in the open position by a compression spring. This spring (obviously of material compatible with the medium) is light weight and very durable, in fact there is no difference in weight between this new system and older competing products. The spring will be one piece from end- to-end and will have the spring part occupying about two feet in the middle of the hose. The spring will have on each side (again this is one piece) straight metal spring steel that will insert into the flapper holding it open. This basically looks like a two foot spring with about 9 feet of straight spring steel protruding from each side. The introduction of advanced spring technology has several important advantages:

The LifeGuard Tri-Bolt Breakaway Hose is designed to separate at any angle when subjected to a designated pull force. In case of separation, its patent pending design assures that not less than two bolts will separate causing the internal valves to engage and the piping to remain intact with flow stopped on both ends of the hose. The LifeGuard Tri-Bolt Breakaway Hose is combined with a UHMWP tube chemical transfer hose designed to meet the bulk hauling and chemical industries’ most demanding requirements. It is light weight, flexible but also rugged. Chemical UHMWP will handle chemicals with a phase change to gas down to 60°F. Read More

We are excited about our global approach towards expanding the scope of our offering to extremely high quality standard hose assemblies, hose assemblies with our latest proprietary back-check valve to avoid product contamination and our improved safety hoses. As you will note in the diagram below from our recent patent filing, we have (among other things) increased the distance between the plunger valve and the seat (note 100 below) to allow better flow and, most importantly, mitigate the possibility of adiabatic compression.

If you have questions, comments or feedback, please feel free to contact us.

We are ready to help!